Precedente

Successivo

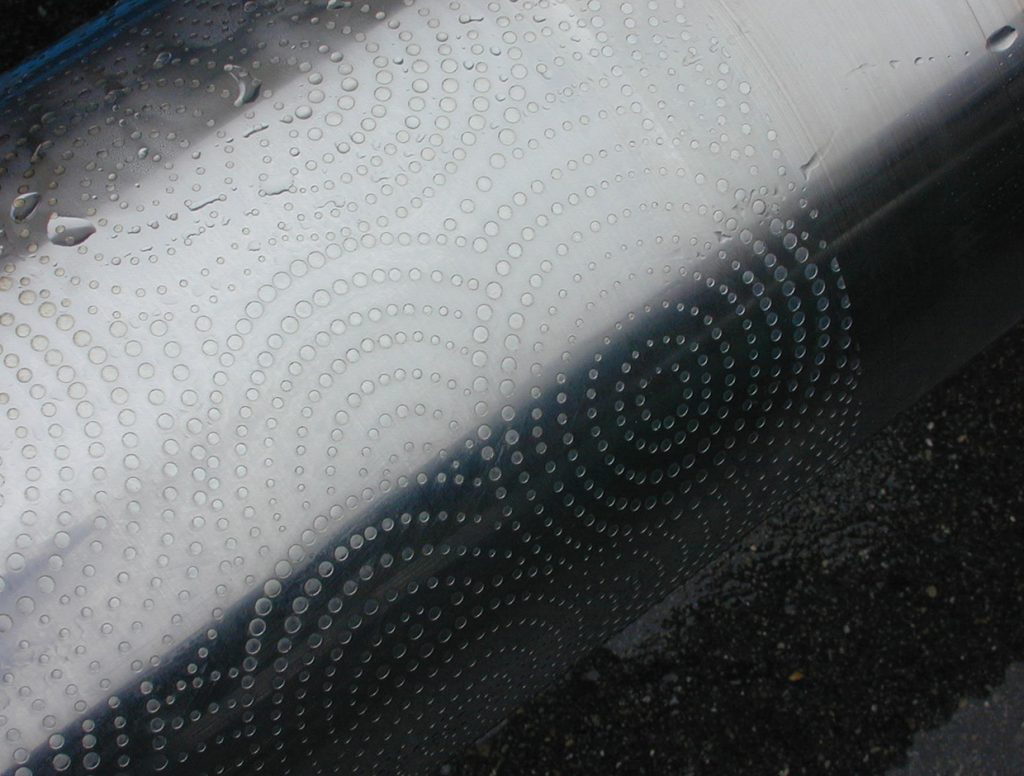

SURFACE CLEANING

leaving the original outline undamaged

Application examples: molds surfaces – surfaces of printing cylinders – embossing – matrices – negative/positive outlines – flat clichés or on rotary cylinders – etc.

- The optimization of the surface treated with Airmation UHP system results in a full restoration both of the original outline, normally left completely undamaged, and of the details. In particular, it is the details that excel and benefit from this technology. This is due to the cleaning action carried out through revolving micro-jets that, thanks to high pressure and different inclinations, penetrate into the details of the surface reliefs (e. g. into the details of micro-carved or micro-perforated drawings, embossing, knurling, markings, and the like).

- Any kind of impurity can be selectively removed from a great number of surfaces, stamps, structural and mechanical parts.

- In treating peculiar surfaces or tightly clinging sediments, it is crucial to deeply understand the adopted process in order to leave the treated surface undamaged.

Airmation has a considerable experience in outlining solutions and systems in which many parameters of application are deemed essential: pressure, nozzles, revolving speed, progress selection, etc. - Cleaning is carried out deeply and allows a subsequent optimum reuse of the cleaned manufacture, especially in those cases in which it is deemed necessary a perfect and reproducible aesthetic effect

- Water technology is the only one that provides a result with no latent incompatibilities, that may occur to the surfaces when they are cleaned using traditional technologies such as salts, acids, chemistry, etc

[member] [/member]

[/member]

back